In the battery industry, hardy design refers to a battery’s ability to withstand harsh operating conditions, deliver consistent performance, and maintain long service life even under heavy usage, irregular power conditions, and extreme environments. A hardy battery is engineered for strength, durability, reliability, and safety, making it ideal for automotive, inverter, UPS, industrial, and solar applications.

🔋 Key Elements of Hardy Battery Design

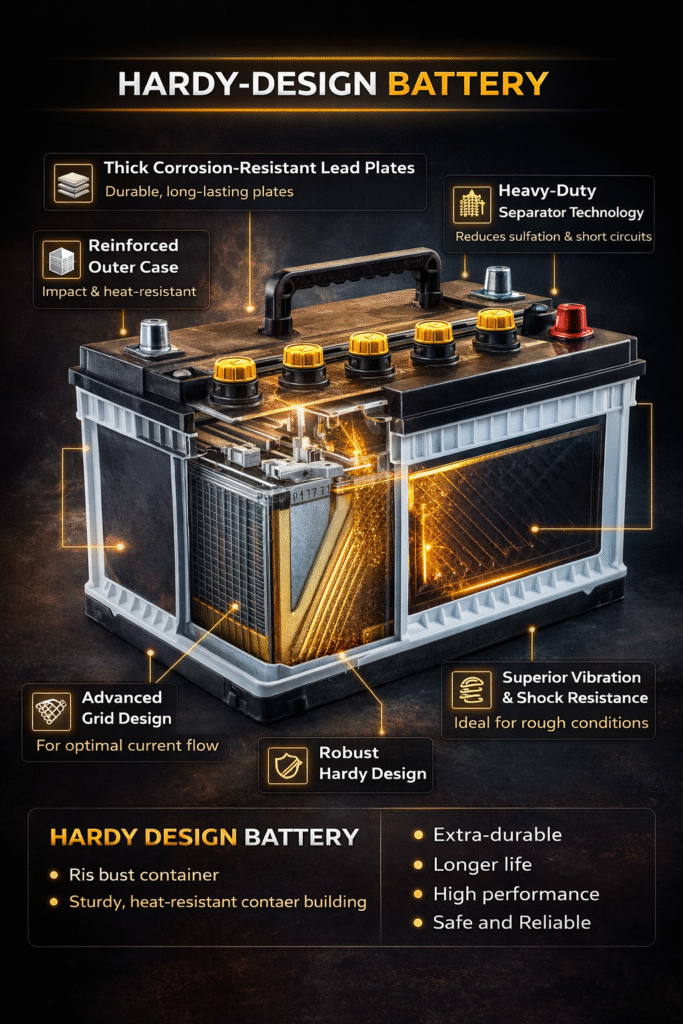

1. Robust Container & Structural Strength

Hardy batteries use high-impact, heat-resistant polypropylene or reinforced ABS containers.

- Resistant to cracks, vibrations, and shocks

- Withstands high temperatures common in Indian climates

- Prevents deformation during long charging cycles

This strong outer casing ensures the battery remains safe and leak-free even in rough usage conditions.

2. Thick, Corrosion-Resistant Lead Plates

One of the most critical aspects of a hardy design is extra-thick battery plates.

- Made from high-purity lead or advanced lead-calcium / lead-selenium alloys

- Designed to resist corrosion and plate shedding

- Enables deeper discharge cycles without performance loss

Thicker plates directly translate into longer backup time and extended battery life.

3. Advanced Grid & Plate Design

Hardy batteries use computer-designed grid structures that improve:

- Current flow efficiency

- Mechanical strength of plates

- Resistance to thermal expansion

Optimized grid patterns reduce internal resistance and ensure stable output even during high load demand.

4. High-Density Active Material

The active material pasted on the plates is formulated with:

- High porosity for better chemical reactions

- Strong adhesion to prevent shedding

- Uniform distribution for consistent performance

This ensures faster charge acceptance, higher cranking power, and reliable backup during long power cuts.

5. Vibration & Shock Resistance

Hardy design batteries are specially built to handle:

- Continuous road vibrations (automotive use)

- Frequent inverter on-off cycles

- Industrial machinery vibrations

Plate locking systems and reinforced separators prevent internal damage, making the battery highly reliable in tough conditions.

6. Enhanced Separator Technology

Advanced microporous separators are used to:

- Prevent short circuits

- Improve electrolyte circulation

- Reduce internal heat build-up

This enhances safety and allows the battery to operate efficiently even under heavy loads.

7. Optimized Electrolyte Management

Hardy batteries use special electrolyte formulations and controlled acid levels to:

- Reduce water loss

- Minimize sulfation

- Improve deep-cycle endurance

In maintenance-free batteries, this design ensures zero or very low water top-up requirement.

8. Superior Thermal Management

Heat is one of the biggest enemies of battery life. Hardy design includes:

- Heat-resistant materials

- Improved ventilation systems

- Optimized internal spacing

This protects the battery from overheating, thermal runaway, and premature failure.

9. Leak-Proof & Safety-Focused Construction

- Flame-arrestor vents to prevent external sparks

- Sealed terminals to avoid acid leakage

- Short-circuit and overpressure protection

These features make hardy batteries safe for home, office, and industrial environments.

✅ Benefits of Hardy Design Batteries

- Longer battery life

- Reliable performance in extreme heat & power fluctuations

- Low maintenance

- Higher load handling capacity

- Ideal for Indian power and climate conditions

🔧 Applications of Hardy Design Batteries

- Car & commercial vehicle batteries

- Home inverter & UPS batteries

- Solar energy storage systems

- Industrial backup & telecom batteries

Conclusion

A hardy design battery is not just about power—it’s about endurance, reliability, and safety. With reinforced construction, thick plates, advanced materials, and intelligent engineering, hardy batteries deliver consistent performance even under the toughest operating conditions, making them the preferred choice for long-term, dependable power backup.